Talc in Plastics

Enhancing performance, efficiency and sustainability in polymer applications

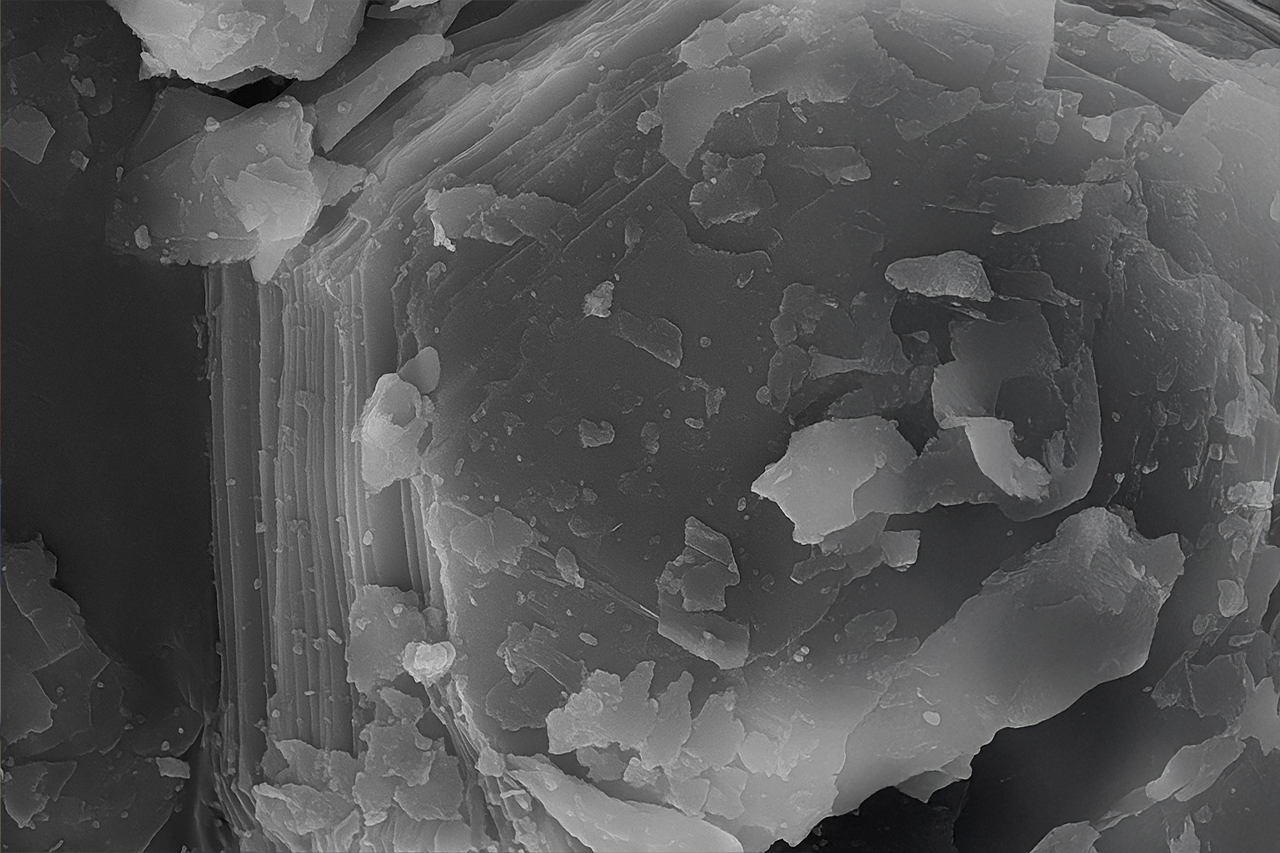

Talc is a widely used mineral in plastics, acting as a multifunctional additive to improve mechanical, thermal, and environmental performance. Its lamellar structure and chemical inertness make it ideal for automotive, packaging, consumer goods, and biopolymer applications.

Functional Roles of Talc in Plastics

Talc functions as a:

Reinforcing filler, improving stiffness, dimensional stability, and impact resistance.

Antiblocking agent, especially in film applications.

Typical applications include:

Automotive parts

Bumpers, dashboards, under-hood components

Appliances and consumer goods

Rigidity, surface finish, heat resistance

Packaging

Weight reduction, cost savings, improved strength

Recyclable compounds

Restoring properties in post-consumer plastics

Technical Benefits of Talc in Plastics

Talc functions as a:

Higher stiffness-to-weight ratio

Enhanced dimensional stability (reduced shrinkage and warping)

Increased heat resistance, especially in PP compounds

Better scratch resistance

Improved flow and moldability, reducing energy consumption

MinTalc® Grades and Compatibility

MinTalc® grades are engineered for:

Polypropylene (PP)

Polyethylene (PE)

Polyamide (PA)

They are available in various fineness levels and aspect ratios to meet technical and economic formulation goals.

PVC

Polystyrene (PS)

Engineering plastics

Compacting Technology:

Added Value of Compacted Talc

Global Minerals Technologies offers compacted MinTalc® grades that:

Improve handling and reduce dust

Ensure better dispersion in compounding

Optimize logistics and feeding in extrusion processes

New product in development. Soon in our portfolio.

Performance by Application Area

Automotive & Industrial Applications (PP, PA)

MinTalc® as a functional filler:

PP Compounds

+15–20°C in HDT

Shrinkage <0.8%

Cost savings (10–30%) replacing glass fiber/virgin resin

Nylons (PA6/66)

Flexural modulus up to 5000 MPa

–50% moisture uptake

Dimensional stability under humidity cycling

Scratch and Mechanical Enhancement:

MinTalc ScratchPro ST / ArmorShield™

MinTalc produces high-quality fine talc grades used as functional fillers in the automotive and paint/ink industries.

Surface-functionalized Talc grades designed for polyolefin-based automotive compounds, offering enhanced mechanical properties and improved long term scratch resistance.

Key Findings:

Surface-treated talc improves scratch resistance up to 38%.

Mechanical properties remain stable or improve.

Best results with 2–3% additive loadings.

Key Applications:

Automotive interiors (dashboard, door panels)

Exterior trim

Under-hood components

Tech: High-Speed Surface Treatment (HSST)

Functional additives bonded at molecular level

Uniform hydrophobic surface

Laminar structure preserved

Engineering Plastics

MinTalc® as a performance additive:

ABS: Scratch resistance (ASTM D3363 ≥H), flame retardancy (UL94 V-0)

PC blends: Optimized melt flow, haze <10% for LED/optical applications

Nucleating Agent Applications

PS/HIPS: −15–20% cycle time, improved surface finish, +10–15°C HDT

EPS/XPS: Uniform cell structure, better thermal insulation (0.033 W/m·K)

MinTalc®in Packaging and Biopolymers

Key advantatges:

Higher stiffness and mechanical strength

Improved heat resistance

Lower resin use without quality loss

Better moldability

Biopolymer compatibility

Film & Plastic Bags: Performance Enhancers

Materials: LDPE, LLDPE

Anti-blocking, better stretch performance

Food Packaging: Functional Additives

Materials: PP, PLA

Enhances oxygen/moisture barrier

Enables stable thermoforming

Bioplastics: Sustainable Solutions

Tackles brittleness and heat sensitivity

Improves extrusion and molding

Enables durable, compostable items

Applications

- Compostable packaging

- Molded cutlery

- Eco-friendly durable bags

MinTalc®as Nucleating Agent in Biopolymers

Advantages

- Finer particles = better surface area

- Reduces energy and cooling time

- Broad polymer compatibility

Why Choose MinTalc® by Global Minerals Technologies

Tailored for conventional and bio-based plastics

Proven mechanical and thermal benefits

Enabler of circular economy

Advanced compacting and surface treatment technologies

Technical and commercial support

For inquiries related to products, documentation, regulatory compliance or specific technical requirements, please contact our team.

Formulari de Contacte 2025

"*" indicates required fields